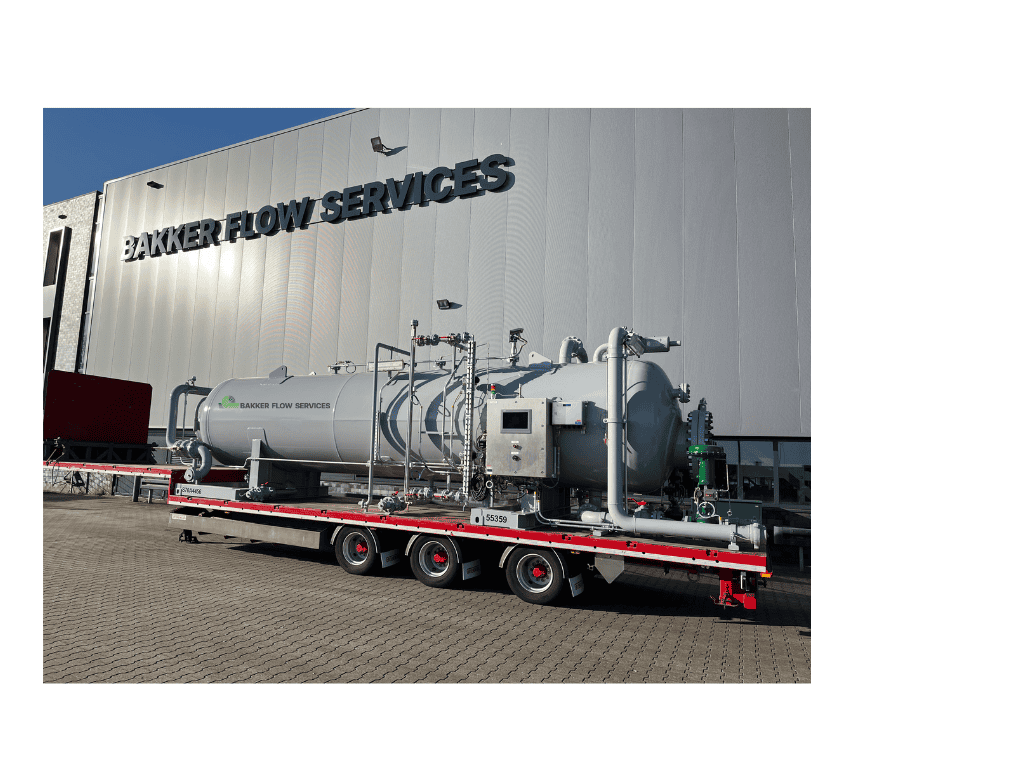

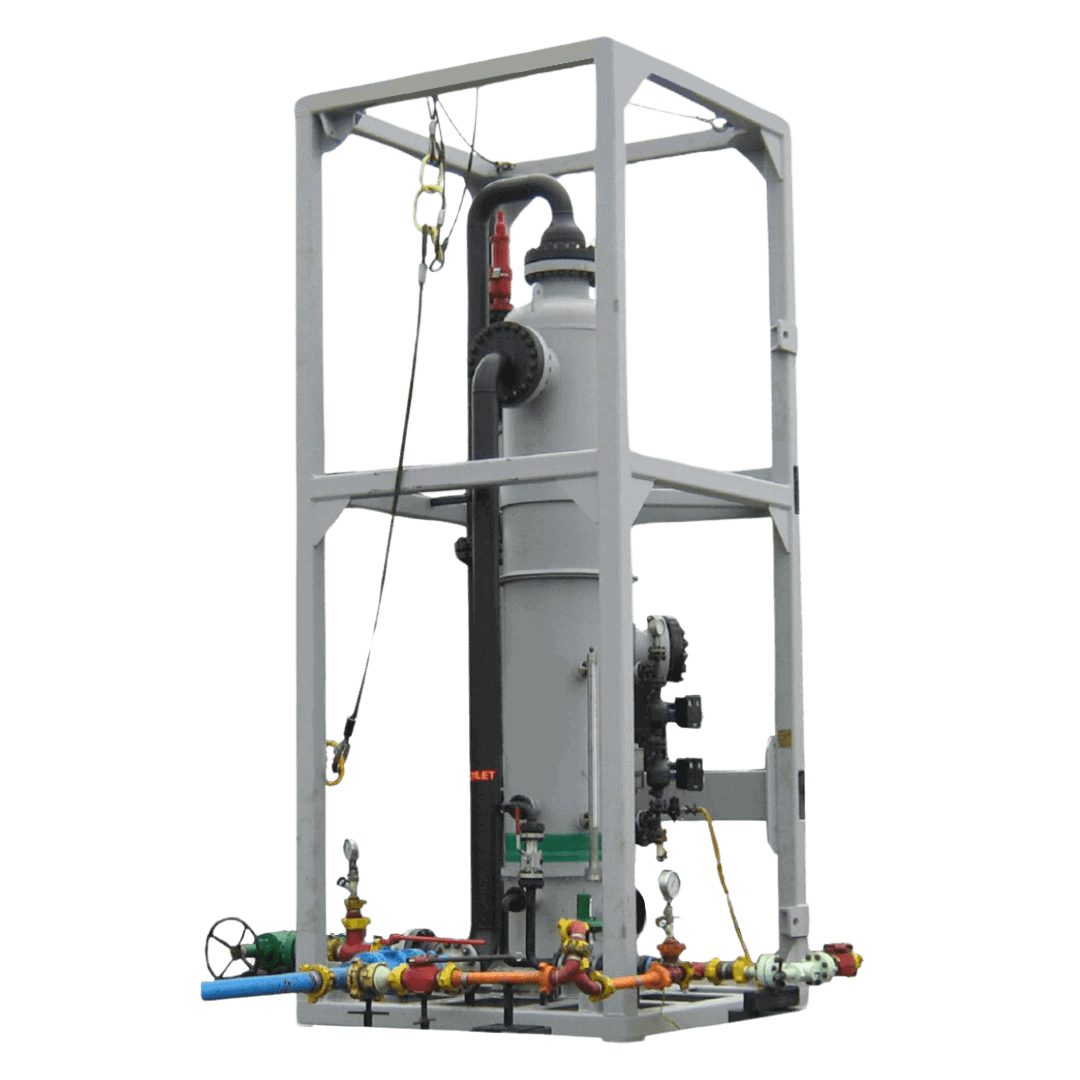

Mobile Well Testing Setup

€ 0,00

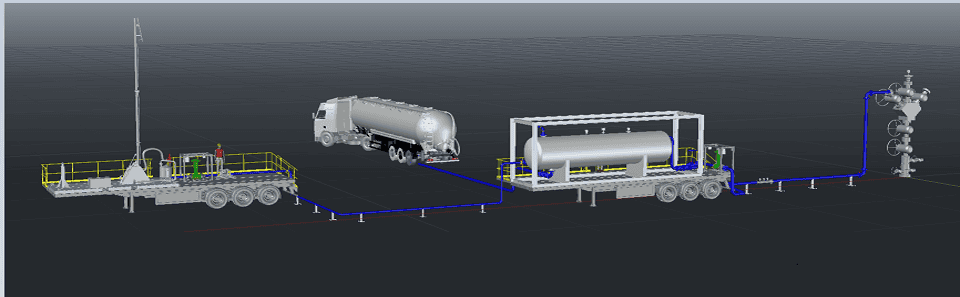

Get ready to take well testing to the next level with our innovative, fully mobile solution — engineered for maximum efficiency, significant cost savings, and effortless deployment.

Whether you’re after flexibility, speed, or reliability, our cutting-edge setup delivers it all — empowering you to get the most out of your operations, faster, smarter, and more effectively than ever before.

Features:

- Rapid Rig-Up/Rig-Down: Drastically reduce setup and teardown times. Less downtime means faster turnarounds and smoother project execution, so you stay ahead of schedule.

- Compact Footprint: Designed for mobility, our setup offers logistical and transport advantages while minimizing environmental impact — ideal for remote or hard-to-access locations.

- Fully Self-Sufficient: Our system is completely autonomous, powered by the latest in well testing tech. It’s plug-and-play simplicity for the most demanding environments.

- Peak Efficiency: Experience operational excellence with seamless integration, advanced systems, and rapid deployment. Our setup lets you do more with less.

- Cost-Effective: Time savings, space efficiency, and low setup costs mean one thing: real savings. Optimize your budget without sacrificing performance or reliability.

Please note that this item is not solely available for rental, but can be acquired with our personnel. For more information and to explore available options, please don't hesitate to contact us.

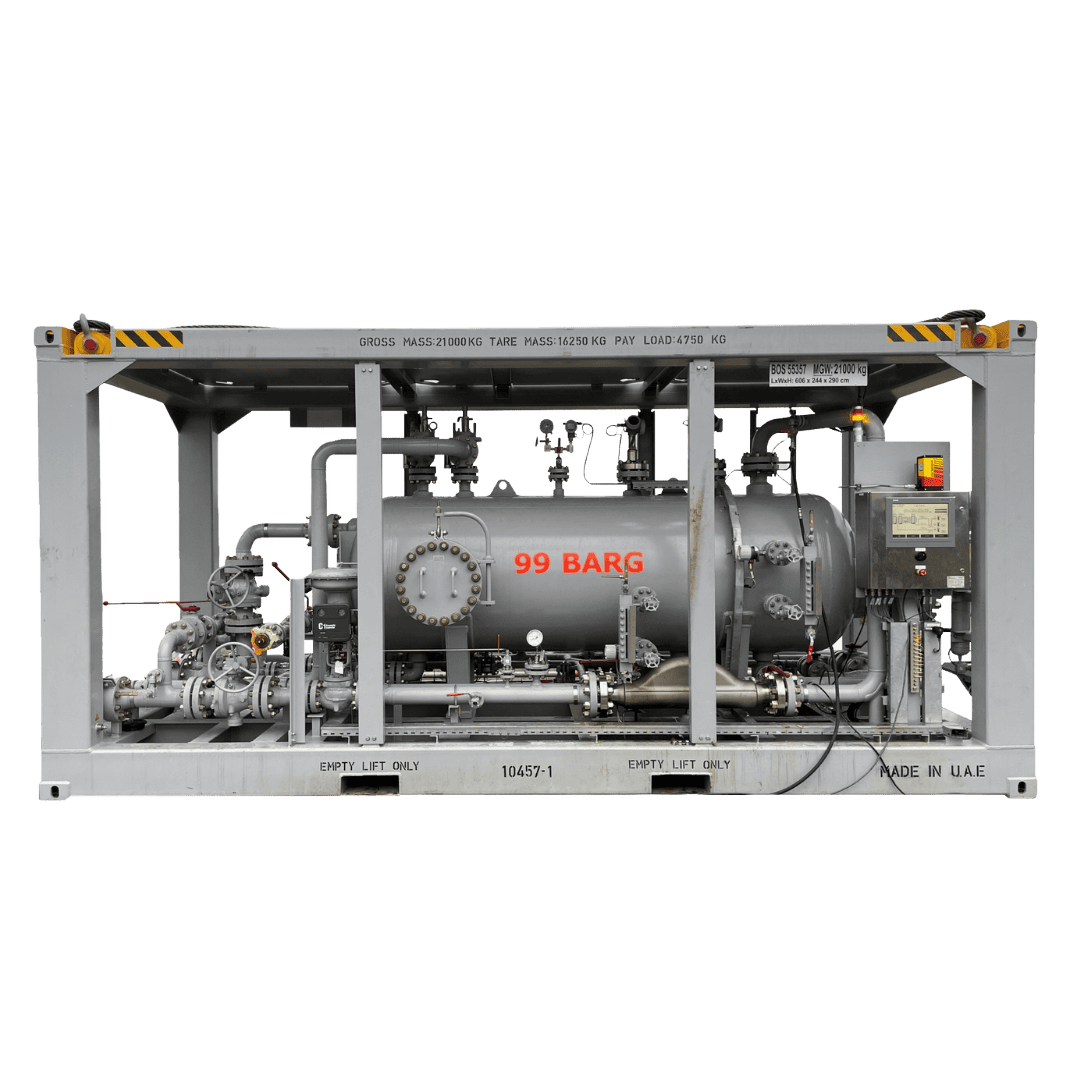

Technical specifications

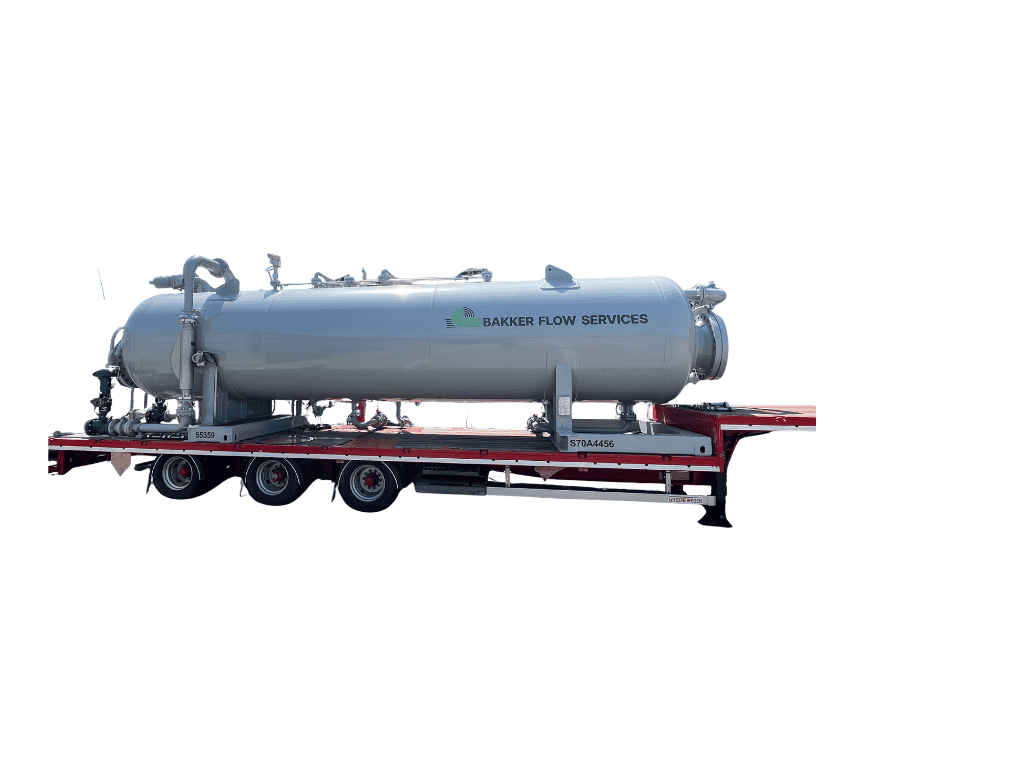

| Type | Mobile Well Testing Setup |

|---|---|

| Flow Liquid | 125m³/h |

| Flow Gas | >30.000Nm3/h |

| Efficiency | Up to ≥99%” depending on flow parameters |

| Design Pressure | 46barg |

| Design Temperature | -29°C / 121°C |

| Inlet | 6” 206 female |

| Gas Outlet | 4” 206 male |

| Water outlet | 6” 206 male |

| Skim Connection | 4” 300# RF |

| PSV Relief | 6” 206 male |

| w/s Bottom Drain | 3” 206 female |

| Water Drain | 3” 206 female |

| Purge Connection | 2” 206 female |

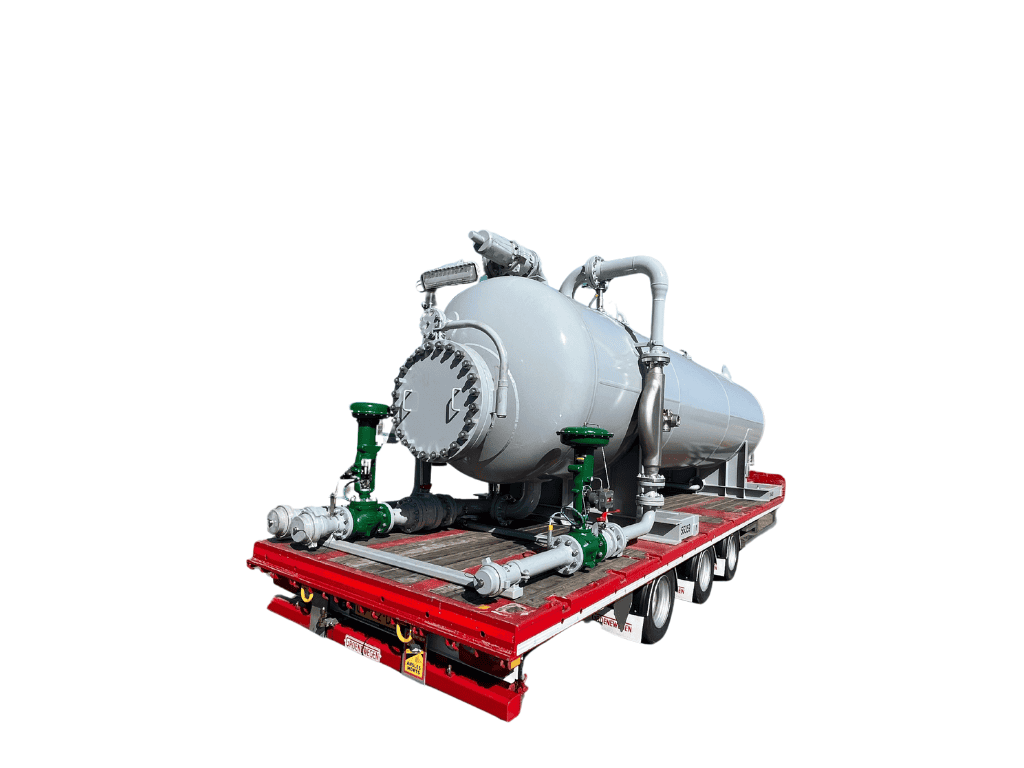

| 2 x Manhole | 24” 300# RF |

| Equipment Dimensions | 2,5 x 13,95mtr |

| Weight Mobile Separator | 17,7T |

Description

Control Strategy

Inlet Control:

The influx of mixture into the separator can be controlled by the source, a manual or automatic control or choke valve, depending on the source and process. No flow meter is present on the inlet. However, the flow rate of gas leaving the separator through the gas outlet is measured with a coriolis mass flow meter. There is also an option to install an external liquid flow meter to measure the liquid flow rate leaving the separator through the liquid outlet. Using this information, manual or automatic control valves can be used to regulate the inflow.

Gas outlet measurement:

The gas outlet is equipped with a flow meter (FITQ/QIT: Coriolis mass flow meter) that measures the gas flow. This meter provides data for gas outlet monitoring and logging.

Level control:

Liquid levels in the separator are continuously monitored by a level meter (LT: Level via guided wave radar). Two level switches (LS: Level Switches) act as protection for high and low levels. A level control valve (LCV) is used to control the fluid level. When the level exceeds the set limits, the valve is automatically opened or closed to maintain the proper level with PID controller.

Example: Set level is 50%. When the fluid level rises above 50%, the level control valve opens to drain excess fluid. Depending on the incoming flow, the valve opening will be adjusted to maintain the level at 50%. In case of low level alarm (LSLL), a warning is activated to prevent the separator from gas passage through the water outlet.

Pressure Control:

The pressure in the separator is measured by a pressure transmitter (PIT). A pressure control valve (PCV) is controlled by a PID controller for the discharge of gas to keep the pressure within set limits. Also present is a PSHH pressure switch that activates when the pressure becomes too high. In addition, to ensure the integrity of the separator, a pressure safety valve (PSV) is installed that activates should the pressure continue to rise at 46barg.

Example: The process becomes uncontrolled and the pressure rises higher than the set desired pressure in PID controller. It comes up to the set pressure of PSHH pressure switch and will be triggered. An alarm will sound and the ESD system will be triggered. If the pressure continues to rise, the safety valve (PSV) will open. This immediately releases the pressure ensuring the integrity of the separator.

Temperature monitoring:

The temperature of the gas and liquid in the separator is monitored by temperature transmitters (TIT) on the separator and by two external temperature transmitters (TT). These measurements are used to monitor the process and detect deviations early. The additional external measurements provide additional control, especially in operations where temperature variations play a major role.

External Fluid Flow Measurement:

In addition to the gas flow measurement, it is possible to install an external fluid flow meter (FITQaux) to measure the fluid flow leaving through the water outlet. This additional measurement helps determine the fluid discharge and optimizes the fluid management strategy.