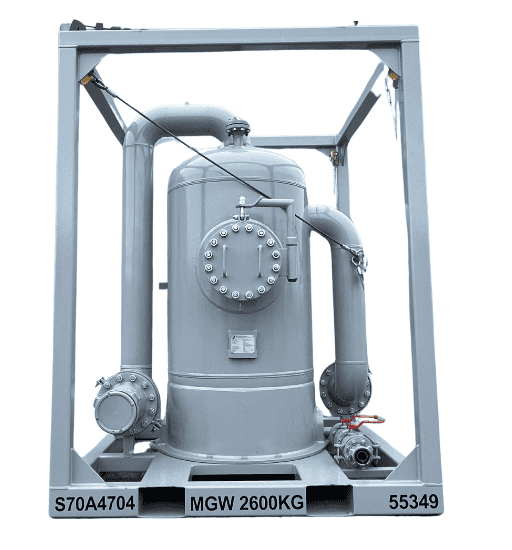

Knockout Vessel Flare, 19 Bar, 0,7M³

€ 0,00

Our knockout vessel flare is the ultimate solution for safeguarding downstream equipment from abrasive particles. Engineered with precision, this knockout vessel flare is adept at efficiently separating small traces of sand and other solid debris, ensuring the smooth operation and longevity of your equipment.

Technical specifications

| Design pressure | 19 barg |

|---|---|

| Design temperature | -29/+38 ⁰C |

| Single ph. gas flow based on methane | 570.000 Nm3/d @ 17 barg |

| Volume | 0,7m3 |

| Medium | Oil / gas |

| Inlet | 6” 150#RF |

| Gas outlet | 6” 150#RF |

| Bottom drain | 2” fig.1502 F |

| Skid | Onshore |

| Service | Sour (H2S) |

| Dimensions (L x W x H) | 340 x 125 x 140 cm |

| Transport weight | 1950 kg |

| Features | Level gauge with magnetic float |

| Certification | NACE NR-01-75 / PD 5500 2003 Cat.1 |

Description

This knockout vessel is designed to separate liquid from gas by reducing the gas velocity, allowing entrained liquid droplets to settle out. It is most commonly used upstream of gas combustion equipment, such as flare systems, but can also serve to recover valuable entrained products. Knockout drums are typically associated with natural gas processing and refinery operations. This knockout vessel are simple in construction, lacking internal components.

Excess liquid in a gas stream can reduce combustion efficiency and create serious safety hazards, such as flaming rain-like sprays during process upsets. By capturing and removing a large portion of the entrained liquid before the gas continues on, the knockout drum helps prevent such issues. The separated liquid is then either drained or pumped out of the vessel.

The vessel’s large internal volume relative to the inlet and outlet piping allows for significant reduction in gas velocity, which aids in the settling of liquid and solid particles. This makes knockout vessels particularly effective in situations with high entrained liquid content or where upset conditions could result in slugs of liquid entering the system.

For applications requiring higher removal efficiency, especially with finer droplets or lower tolerance for liquid carryover, we have dedicated gas-liquid separators available instead of a knockout vessel.